NAV

Search

Based on advanced process equipment and testing methods, the main products are produced by CAD, CAE and other advanced auxiliary design and manufacturing methods.

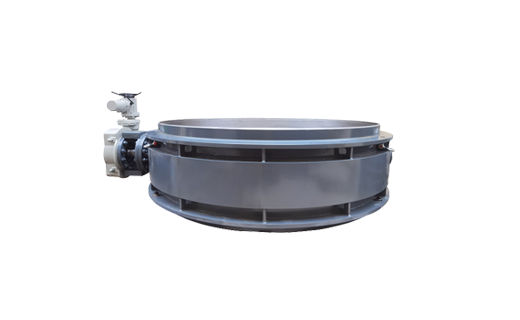

Introduced French TOV design. Triple Offset design in the truest sense of the word. The moment the butterfly valve is opened, the disc is completely detached from the valve seat without any friction and interference. Forward/Reverse: Isobaric sealing in both directions. LEAKAGE LEVEL: EN12266-1 CLASS A / FCI 70-2 CLASS VI Double-break valve shaft design increases valve flow capacity

See details

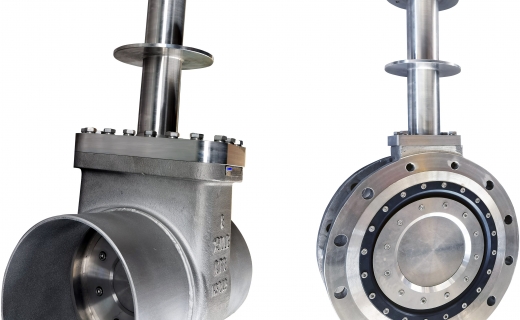

Two-way airtight seal, zero leakage, the valve ensures the sealing performance

See details

TOP entry/Side top entry Cryogenic triple offset butterfly valve TOP entry Cryogenic ball valve LNG storage and transportation, industrial gas storage, air separation.

See details

Suitable for various working conditions such as butterfly valve and vacuum pumping of air cooling system in thermal power plant

See details

Suitable for high temperature and wear-resistant working conditions, using a variety of hardening treatment processes

See details

Single valve seat, full bore design, reliable sealing and convenient operation

See details

STARRYSKY VALVE is a well-known valve manufacturing company in China. The manufacturing plant is located in Yancheng, Jiangsu.

Branches in Beijing, Shanghai, Xi'an and Chengdu in Mainland China;

STARRYSKY VALVE introduces advanced French technology to produce valve products,

Has developed into a valve manufacturing company integrating R&D, design, manufacturing, inspection and marketing.

Application

Honor

Established

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

Designed for high temperature environment pressure sealing, from material to manufacturing process through strict control, we provide customers with a wide range of valve solutions to meet the demanding requirements of power station facilities

The strength test of the welded ball valve uses water as the medium to conduct the strength test. It is necessary to weld high pressure caps at the two ends of the welded ball valve to make the ball of the ball valve in the open position of 45 degrees, and use the pressure test valves on the sleeves on both sides to weld the ball valve. Inject water into it to increase the pressure to 1.5 times the nominal pressure of the welded ball valve, and keep the pressure for 15 minutes. If there is no leakage of the medium, it means that there is no leakage as normal.

The integrated high temperature ball valve has the advantages of stable performance, reliable sealing, low friction, light switch, high temperature resistance, wear resistance, oil resistance, corrosion resistance, long service life, etc.